Hydroponics

Content

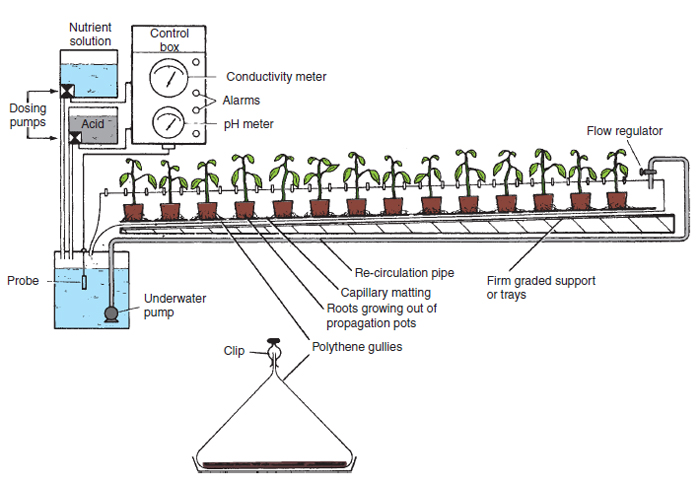

Hydroponics (water culture) involves the growing of plants in water. The term often includes the growing of plants in solid rooting medium watered with a complete nutrient solution, which is more accurately called ‘aggregate cultur’. Plants can be grown in nutrient solutions with no solid material so long as the roots receive oxygen and suitable anchorage and support is provided. The advantages of hydroponics, compared with soil, in temperate areas includes accurate control of the nutrition of the plant and hence better growth and yield. There is a constant supply of available water to the roots. Evaporation is greatly reduced and loss of water and nutrients through drainage is minimal in recirculating systems. There can be a reduction in labour and growing medium costs and a quicker ‘turn round’ time between crops in protected culture. The disadvantages include the high initial costs of construction and the controls of the more elaborate automated systems. Active roots require a constant supply of oxygen, but oxygen only moves slowly through water. This can be resolved by pumping air through the water that the plants are grown in, but it is usually achieved on a large scale by growing in thin films of water as created in the nutrient film technique (NFT) or a variation on the very much older aggregate culture methods. Nutrient film technique (NFT) This is a method of growing plants in a shallow stream of nutrient solution continuously circulated along plastic troughs or gullies. The method is commercially possible because of the development of relatively cheap non-phytotoxic plastics to form the troughs, pipes and tanks (see Figure 22.5). There is no solid rooting medium and a mat of roots develops in the nutrient solution and in the moist atmosphere above it. Nutrient solution is lifted by a pump to feed the gullies directly or via a header tank. The ideal flow rate through the gullies appears to be 4 litres per minute. The gullies have a flat bottom, often lined with capillary matting to ensure a thin film throughout the trough. They are commonly made of disposable black or white polythene set on a graded soil or on adjustable trays. There must be an even slope with a minimum gradient of 1 in 100; areas of deeper liquid stagnate and adversely affect root growth (see aerobic conditions).

The nutrient solution can be prepared on site from basic ingredients or proprietary mixes. It is essential that allowance be made for the local water quality, particularly with regard to the micro-elements, such as boron or zinc, which can become concentrated to toxic levels in the circulating solution. The nutrient level is monitored with a conductivity meter and by careful observation of the plants. Maintenance of pH between 6 and 6.5 is also very important. Nutrient and pH control is achieved using, as appropriate, a nutrient mix, nitric acid or phosphoric acid to lower pH and, where water supplies are too acid, potassium hydroxide to raise pH. Great care and safety precautions are necessary when handling the concentrated acids during preparation. The commercial NFT installations have automatic control equipment in which conductivity and pH meters are linked to dosage pumps. The high and low level points also trigger visual or audible alarms in case of dosage pump failure. Dependence on the equipment may necessitate the grower installing failsafe devices, a second lift pump and a standby generator. A variation on this method is to grow crops such as lettuce in gullies on suitably graded glass house floors (see Figure 22.6).

Aggregate culture In aggregate culture the nutrient solution is broken up into water films by an essentially inert solid medium, such as coarse sand or gravel. More commonly today materials such as rockwool, perlite, polyurethane foam, duraplast foam or expanded clay aggregates (see Figure 22.7) are used. These are in the form of polythene wrapped slabs or ‘bolsters’ of granules sitting on a polythene covered floor graded across the row. Polyurethane slabs are often placed underneath them to help create even slopes and insulate them from the cooler soil below. These growing containers, on which the plants sit, are drip fed with a complete nutrient solution at the top with the surplus running out through slits near the bottom on the opposite side. When this method was first developed the NFT systems were copied, i.e. the water was recirculated, but it was soon found to be difficult where the quality of water was poor and there was a risk of a build-up of waterborne pathogens and trace elements. It was found that the surplus nutrient solution was most easily managed by allowing it to run to waste into the soil. However, this open system presents environmental problems and increasingly a closed system has had to be adopted. It is now becoming more usual to run the waste to a storage sump via collection gullies or pipes. Some of this can be used to irrigate outdoor crops if nearby. To recirculate the water it is necessary to have equipment to remove the excess salts or accept a gradual deterioration of the nutrient solution and then flush it out to a sump when it becomes unacceptable. Sources of infection such as Pythium are minimized by isolation from soil and using clean water; the risks of recirculating pathogens is addressed by using one of the four main methods of sterilization (see water quality).

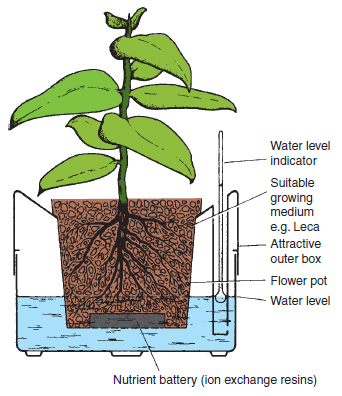

Several types of expanded clay aggregates used in the building industry, such as Leca or Hortag, have been used particularly in interior landscaping (see Figure 22.3). Smooth but porous granules 4–8 mm in diameter, giving a capillary rise of about 100 mm, are used to create an ideal rooting environment with a dry surface which makes it an attractive method of displaying house plants (see Figure 22.8). All forms of aggregate culture require feeding with all essential minerals. Trace element deficiencies occur less frequently when clay aggregates are used. Ion exchange resins are an ideal fertilizer formulation in these circumstances because the nutrients are released slowly, remove harmful chlorides and fluorides from irrigation water, and aid pH control. |

||||||||||||||||||||||||||||