The Autoclave

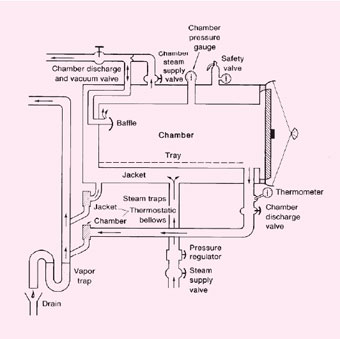

The autoclave is a steam-pressure sterilizer. Steam is the vapor given off by water when it boils at 100°C. If steam is trapped and compressed, its temperature rises as the pressure on it increases. As pressure is exerted on a vapor or gas to keep it enclosed within a certain area, the energy of the gaseous molecules is concentrated and exerts equal pressure against the opposing force. The energy of pressurized gas generates heat as well as force. Thus, the temperature of steam produced at 100°C rises sharply above this level if the steam is trapped within a chamber that permits it to accumulate but not to escape. A kitchen pressure cooker illustrates this principle because it is, indeed, an “autoclave.” When a pressure cooker containing a little water is placed over a hot burner, the water soon comes to a boil. If the lid of the cooker is then clamped down tightly while heating continues, steam continues to be generated but, having nowhere to go, creates pressure as its temperature climbs steeply. This device may be used in the kitchen to speed cooking of food, because pressurized steam and its high temperature (120 to 125°C) penetrates raw meats and vegetables much more quickly than does boiling water or its dissipating steam. In the process, any microorganisms that may also be present are similarly penetrated by the hot pressurized steam and destroyed.Essentially, an autoclave is a large, heavy-walled chamber with a steam inlet and an air outlet (fig. 13.1). It can be sealed to force steam accumulation. Steam (being lighter but hotter than air) is admitted through an inlet pipe in the upper part of the rear wall. As it rushes in, it pushes the cool air in the chamber forward and down through an air discharge line in the floor of the chamber at its front. When all the cool air has been pushed down the line, it is followed by hot steam, the temperature of which triggers a thermostatic valve placed in the discharge pipe. The valve closes off the line and then, as steam continues to enter the sealed chamber, pressure and temperature begin to build up quickly. The barometric pressure of normal atmosphere is about 15 lb to the square inch. Within an autoclave, steam pressure can build to 15 to 30 lb per square inch above atmospheric pressure, bringing the temperature up with it to 121 to 123°C. Steam is wet and penetrative to begin with, even at 100°C (the boiling point of water). When raised to a high temperature and driven by pressure, it penetrates thick substances that would be only superficially bathed by steam at atmospheric pressure. Under autoclave conditions, pressurized steam kills bacterial endospores, vegetative bacilli, and other microbial forms quickly and effectively at temperatures much lower and less destructive to materials than are required in a dry-heat oven (160 to 170°C).

Temperature and time are the two essential factors in heat sterilization. In the autoclave (steam-pressure sterilizer), it is the intensity of steam temperature that sterilizes (pressure only provides the means of creating this intensity), when it is given time measured according to the nature of the load in the chamber. In the dry-heat oven, the temperature of the hot air (which is not very penetrative) also sterilizes, but only after enough time has been allowed to heat the oven load and oxidize vital components of microorganisms without damaging materials. Table 13.1 illustrates the influence of pressure on the temperature of steam and, in turn, the influence of temperature on the time required to kill heat-resistant bacterial endospores. Compare these figures with those required for an average oven load—160°C for two hours, 170°C for one hour—and you will see the efficiency of steam-pressure sterilization. Timing should not begin in either oven or autoclave sterilization until the interior chamber has reached sterilizing temperature.

The nature of the load in a heating sterilizing chamber greatly influences the time required to sterilize every item within the load. Steam penetration of thick, bulky, porous articles, such as operating room linen packs, takes much longer than does steam condensation on the surfaces of metal surgical instruments or laboratory glassware (quickly raised to sterilizing temperatures).

|

| Figure 13.1 The autoclave |

|

||||||||||||||||||||||||||

| Table 13.1 Pressure-Temperature-Time Relationships in Steam-Pressure Sterilization | ||||||||||||||||||||||||||

The packaging of individual items (wrapped, plugged, or in a basket) also influences heat penetration, as does the arrangement of the total load in either an autoclave or an oven. In the autoclave, steam must be able to penetrate every surface of every item. In the oven, hot air must circulate freely around each piece in the load to bring it to sterilizing temperature. When sterilizing empty containers in a steam-pressure sterilizer, for example, it is important to consider that they contain cool air. Air is cooler and heavier than steam and cannot be permeated by it; therefore, microorganisms lingering within air pockets existing in or among items placed in an autoclave may survive steam exposure. For this reason, empty containers such as test tubes, syringes, beakers, and flasks, should be laid on their sides so that the air they contain can run out and downward and be replaced by steam. Similarly, packaged materials should be positioned so that air pockets are not created among or between them.

Under routine conditions, properly controlled, steam-pressure sterilization can be accomplished under specific conditions of pressure, time, and temperature.

- 15 to 20 lb of steam pressure

- 121 to 125°C (250 to 256°F) steam temperature

- 15 to 45 minutes, depending on the nature of the load

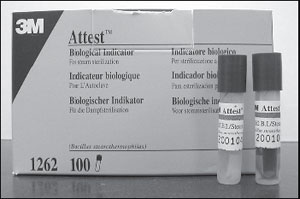

The endospores of a bacterial species called Bacillus stearothermophilus provide a highly critical test of autoclave procedures because they are extremely resistant to the effects of moist or dry heat. As their name implies, they are heat (thermo-) -loving (-philus), but this also means that they require a higher incubation temperature than is optimal for most bacteria. The vegetative cells of B. stearothermophilus grow best at 56°C rather than at the 35°C temperature that is optimal for most pathogenic microorganisms. When dried on paper strips, these endospores provide a good test of oven sterilization techniques. When suspended in broth in sealed ampules, they are very useful for testing autoclave performance.

B. stearothermophilus endospores on paper strips are packaged within paper envelopes that are placed within a load before heat sterilization. After sterilization, they are removed from their envelopes (aseptically), placed in appropriate nutrient broth, incubated at 56°C, and observed for evidence that they did or did not survive the sterilizing technique. Sealed ampules containing endospore suspensions are placed in an autoclave load (they cannot be used to test oven sterilization because they contain liquid), removed, and simply placed, without being opened, in an appropriate incubator (water bath or incubator at 56°C). Within a sealed ampule, endospores have been suspended in a nutrient broth also containing a pH-sensitive dye indicator. If endospores survive autoclaving and germinate again under incubation, vegetative bacilli begin to multiply in the broth. In the process, they use its nutrients, producing acid end products that cause the indicator to change color. They also produce turbidity in the medium.

When strips or ampules are used to test heat-sterilization technique, unheated strip or ampule controls must be incubated also to prove that the endospores were viable to begin with. At the completion of the incubation time, evidence of growth should be observed for the control but not the heated endospore preparations. If the heated test strips or ampules do not show growth by 24 to 48 hours, incubation should be continued for up to 7 days.

The test then may be reported as negative, and the sterilization technique is assumed to have been effective. Patient-care materials included in the sterilized load are then safe to use. If,

|

| Figure 13.2 Strips containing B. stearothermophilus endospores are placed in the autoclave with the material to be sterilized. After the autoclave cycle is completed, each strip is placed into a broth medium and incubated at 56˚C. A second, control strip that has not been autoclaved is incubated in broth at the same time. The endospores on the control strip (left) have germinated and the growing vegetative cells have changed the color of the pH indicator in the broth; the autoclaved endospores (right) have been successfully sterilized and, therefore, the broth remains the original color. |

however, the endospores in the control preparation have not germinated, the test is considered unreliable, and the sterilized material cannot be assumed to be free of contaminating microorganisms. The sterilization procedure should be repeated with a new lot of strips or ampules.

Ampules containing liquid endospore suspensions must be kept refrigerated before use, because warm storage temperatures may permit endospore germination that could be wrongly interpreted. Dried endospore strips may be stored at room temperature because dry endospores are not likely to germinate.

In this exercise, you will have an opportunity to see the sterilizing effects of an autoclave.

| Purpose | To illustrate the use and control of an autoclave |

| Materials | Commercially prepared strips or ampules containing Bacillus stearothermophilus endospores* Nutrient broth (if strips are used) Forceps (if strips are used) 1.0-ml sterile pipettes 56°C water bath or incubator Phenol red glucose broth tubes Six-day-old broth culture of Bacillus subtilis |

*Some commercially available paper strips (Steris Corp., “Spordex Biological Indicators”) contain two types of endospores in combination: those of B. stearothermophilus and also B. subtilis. The latter are less heat resistant than endospores of B. stearothermophilus and do not require a high incubation temperature to germinate (35 to 37°C is satisfactory for incubation of B. subtilis). These combination strips can therefore be used in either a gas sterilizer, an autoclave, or an oven. In a gas sterilizer, the relatively low temperature will destroy B. subtilis endospores but not those of B. stearothermophilus. Strips used for this purpose may then be incubated at 35°C to test for the survival of B. subtilis (the thermophile will not grow), while strips placed in an autoclave or oven load are incubated at 56°C to test for growth of B. stearothermophilus (the mesophile will not grow).

Procedures

- The instructor will discuss and demonstrate the operation of the autoclave.

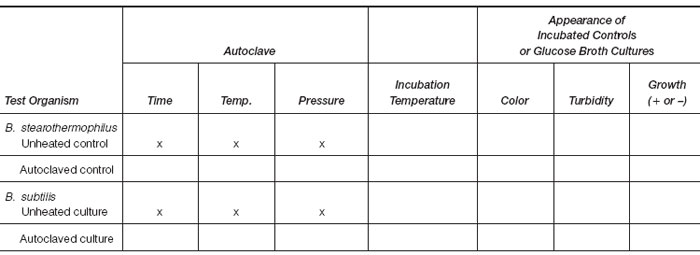

- Inoculate a tube of phenol red glucose broth with 0.1 ml of the B. subtilis culture (finger the pipette). Label it Unheated and place it in the incubator at 35°C for 24 hours.

- Submit the culture of B. subtilis for autoclaving at 15 lb, 121°C, for 15 minutes. Afterward, inoculate a tube of phenol red glucose broth with 0.1 ml of the autoclaved culture. Label it Autoclaved. Incubate the glucose broth at 35°C for 24 hours.

- The instructor will demonstrate the use of endospore controls. An unheated B. stearothermophilus endospore preparation will be placed in a 56°C water bath or incubator. Another will be placed in the autoclave with your subculture of B. subtilis and then incubated.

- If strips are used, the paper envelope of one will be torn open, and the strip will be removed with heat-sterilized forceps and placed in nutrient broth incubated at 56°C. Another will be placed in the autoclave (in its envelope) and heated and then removed and placed in broth.

- If ampules are used, one will be placed (unheated, unopened) in the 56°C water bath or incubator. Another will be autoclaved and then incubated according to the manufacturer’s directions.

- After at least 24 hours of incubation of all cultures, read and examine them for evidence of growth (+) or no growth ( −).

Results

- Record culture results in the table.

- State your interpretation of these results.

- State the method used for timing the autoclave in your experiment.