Production of Yeast Biomass

A comparative composition of nutrients is given in Table 18.3. It is obvious that biomass of S. cerevisiae produced on sugarcane molasses differs from that of bear. Yield of yeast biomass is greatly affected by many factors similar to bacteria. Yield corresponds to growth nutrients, organic wastes, temperature, culture, oxygen, etc. Yield of yeasts is given in parentheses in Table 18.2. Bennett et al. (1969) have given the typical equations for the growth of yeasts on carbohydrates or hydrocarbons:

Carbohydrates:

8n CHO + 0.8 nO2 + 0.19n NH4 + trace elements

n(CH1.7O95N0.12 Ash) + 0.8n CO2+1.3 nH2O + 80,000n KCal.

n(CH1.7O95N0.12 Ash) + 0.8n CO2+1.3 nH2O + 80,000n KCal.Hydrocarbons:

2nCH2+2nO2+0.19n NH4+ trace elements

n(CH1.7O0.5N0.19 Ash) + nCO2 + 1.5 H2O + 200,000n KCal.

n(CH1.7O0.5N0.19 Ash) + nCO2 + 1.5 H2O + 200,000n KCal.Factors Affecting the Yield of Yeast Biomass

Like bacteria, growth and yield of yeasts are also affected by the following factors: (i) organic substrate and nitrogen ratio (optimum C : N ratio favoring high protein content should be between 7:1 and 10:1); (ii) pH of nutrient medium (pH should be in the range of 3.5 to 4.5 to minimize growth of bacterial contaminates); (iii) temperature (it differs from organism to organism). Most yeasts have specific growth rate in the range of 30°C to 34°C. Some strains also grow in the range of 40-45°C; (iv) oxygen (for growth on carbohydrates), O2 required should be 1 g/g of dried cells, and for growth on n-alkanes it should be about 2 g/g dried cells); (v) maintenance of sterile condition through out the process and (vi) suitable strain of yeast.

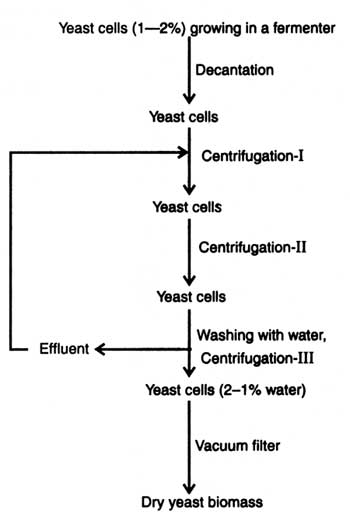

Recovery of Yeast Biomass

Yeast cells are small in size (5-8 m), the density of which reaches to 1.1 g/ml. Post-fermentation treatment of food yeast is shown in Fig. 18.2. Yeast cells are recovered by decantation-centrifugation (including washing) drying treatment methods. After washing undesirable traces of medium are removed which are again recycled for economic reasons. As a result of final harvesting by rotary vacuum filter a cake containing 20-40 per cent dry matter is obtained which is then dried to get a product of 6-10 per cent water content (Riviere, 1977).